Slitting blades are essential tools in many industries, ensuring accurate and clean cuts for various materials. From metal processing to paper, plastic, and textiles, the quality of slitting blades plays a significant role in production efficiency. Maxwell Slitters stands out as a leading provider of high-quality slitting blades, offering durability, precision, and reliability.

Why Slitting Blades Matter

Slitting blades are designed to cut materials into narrower strips or specific shapes. These blades must maintain sharpness and strength to deliver consistent performance. Poor-quality blades can lead to material waste, inaccurate cuts, and production delays. That’s why investing in premium slitting blades is crucial for any industry that requires precision cutting.

Industries That Rely on Slitting Blades

Slitting blades are used in multiple industries, each with specific cutting requirements. Some of the key industries that depend on high-quality slitting blades include:

1. Metal Processing

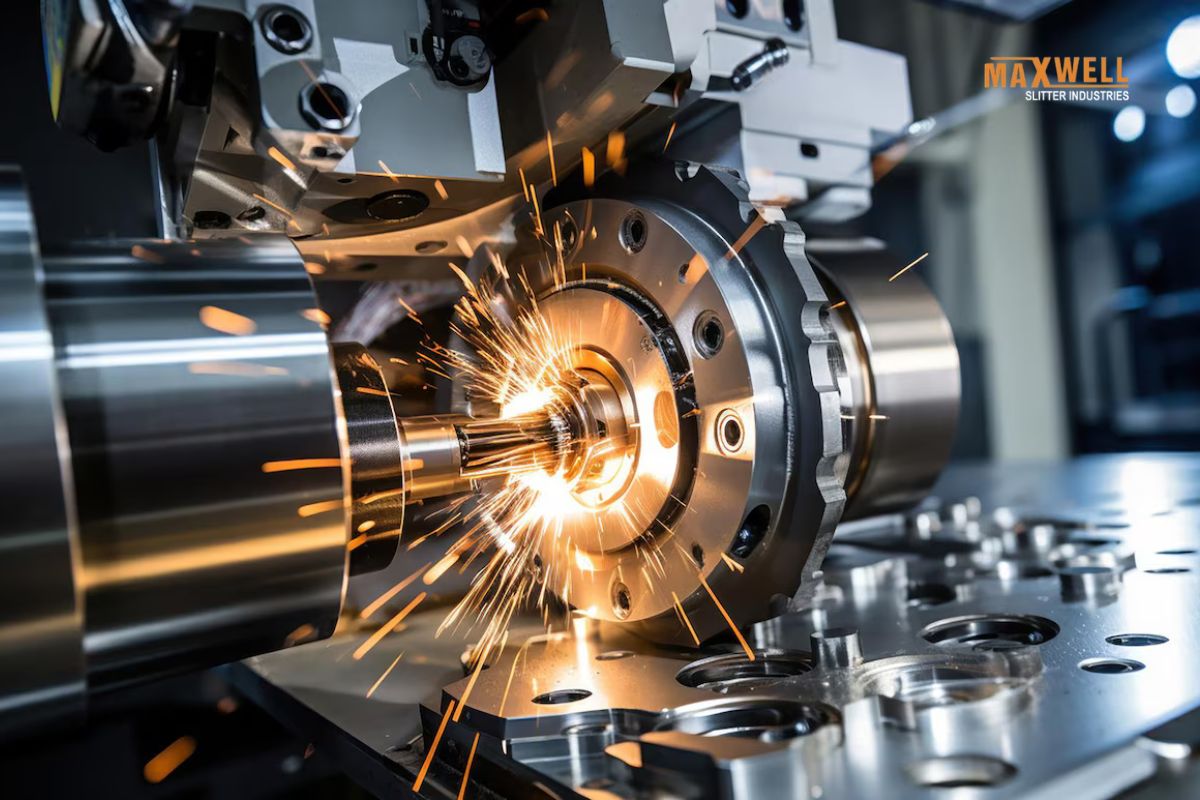

Metal manufacturers use slitting blades to cut sheets, coils, and plates into precise sizes. These blades need to be highly durable to handle tough materials like stainless steel, aluminum, and copper without losing sharpness.

2. Paper and Printing

In the paper and printing industries, slitting blades help create perfectly sized sheets, labels, and rolls. Sharp and reliable blades ensure smooth edges without fraying or tearing, which is essential for high-quality printing and packaging.

3. Plastic and Packaging

Plastic films and packaging materials require precision cuts to ensure uniformity. High-quality slitting blades prevent uneven edges, helping businesses maintain a professional finish on their products.

4. Textile Industry

Fabrics and textiles need clean, smooth cuts to avoid material damage. Precision slitting blades help in cutting delicate and thick fabrics while maintaining their structural integrity.

Why Choose Maxwell Slitters?

Maxwell Slitters is a trusted name in the industry, known for its commitment to quality and innovation. Here’s why businesses rely on Maxwell Slitters for their cutting needs:

1. High-Quality Materials

Maxwell Slitters manufactures blades using premium-grade materials like high-speed steel (HSS) and tungsten carbide. These materials ensure longevity and exceptional cutting performance, reducing the need for frequent replacements.

2. Precision Engineering

Each blade is crafted with precision engineering to deliver accurate cuts with minimal effort. Whether for metal, paper, plastic, or textiles, Maxwell Slitters’ blades guarantee smooth and clean edges.

3. Customization Options

Different industries have unique cutting requirements. Maxwell Slitters provides customized blades tailored to specific needs, ensuring that each customer gets the perfect solution for their application.

4. Durability and Long Lifespan

Slitting blades from Maxwell Slitters are built to last. They maintain their sharpness even after repeated use, reducing downtime and improving production efficiency.

5. Cost-Effective Solutions

Investing in high-quality blades from Maxwell Slitters means fewer replacements and lower operational costs. Their blades provide excellent value by enhancing efficiency and reducing material wastage.

How to Maintain Slitting Blades for Optimal Performance

Proper maintenance can significantly extend the lifespan of slitting blades. Here are some key tips to ensure long-lasting performance:

1. Regular Cleaning

Dust, debris, and residue can accumulate on the blade surface, affecting performance. Cleaning the blades after each use helps maintain sharpness and efficiency.

2. Proper Storage

Store slitting blades in a dry and secure place to prevent rust and physical damage. Using protective covers or cases can help keep them in optimal condition.

3. Routine Inspection

Check blades regularly for signs of wear and tear. Replacing or sharpening blades when necessary ensures consistent cutting quality and prevents production issues.

4. Using the Right Blade for the Material

Choosing the correct blade type for different materials is crucial. Using a blade designed for metal on paper or plastic can cause damage and reduce efficiency.

Conclusion

Maxwell Slitters has established itself as a leading supplier of high-quality slitting blades for various industries. Their commitment to precision, durability, and customer satisfaction makes them a trusted partner for businesses worldwide. By choosing Maxwell Slitters, you ensure superior cutting performance, reduced downtime, and long-term cost savings. Whether for metal, paper, plastic, or textiles, Maxwell Slitters provides the perfect solution for all your precision cutting needs.