Selecting an appropriate hydraulic wrench manufacturer proves essential for obtaining superior operational performance alongside durable equipment. Hydraulic wrenches function as precise tooling systems which serve multiple sectors including both construction and automotive applications for bolt tightening operations. It becomes difficult to find the best manufacturer when numerous companies exist in the market today. Assessing hydraulic wrench manufacturers requires following these fundamental guidelines for making an informed choice.

1. Evaluating hydraulic wrench selection

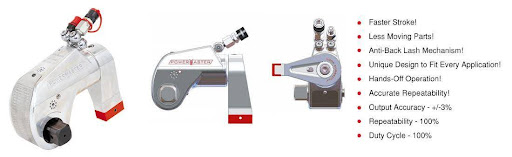

A reliable hydraulic wrench manufacturer selection begins with evaluating their product assortment. Different hose requirements exist between hydraulic torque wrenches and adjustable wrenches and impact wrenches. Manufacturers who excel in their industry should offer an extensive selection of hydraulic wrenches that accommodate multiple uses. Your access to the appropriate tool becomes possible because these manufacturers deliver flexible product choices from heavy industrial work to delicate jobs requiring specific torque management. Check that the manufacturer provides diverse product options which fulfill the different demands of your industry sector.

2. Assess the quality standards and certifications of the manufacturer

A manufacturer’s quality standards remain a basic criterion for selecting hydraulic wrenches. Manufacturers who use international quality standards and follow relevant certification requirements show their dedication to making dependable tools with long service life. Evaluate whether the manufacturing company meets requirements for ISO 9001 quality management standards alongside specific certification standards for their industry. Products from these manufacturers demonstrate high durability through strict adherence to quality standards that guarantee maintenance of safety and performance in demanding environments. Review all feedback for their hydraulic torque wrenches to assess their quality and reliability factors.

3. Consider the manufacturer’s reputation and experience

Manufacturing companies should prioritize both their industry experience and their established reputation. Manufacturers who have built their reputation over multiple years tend to understand hydraulic technology and production techniques better than their counterparts. Manufacturers use their acquired expertise to create hydraulic wrenches that exceed performance requirements for challenging procedures. Select manufacturers that demonstrate an established history of excellence through success in both well-known company orders and established industrial markets. A hydraulic torque wrench manufacturer’s reputation demonstrates the quality standards and operational excellence of their products.

4. Examine the after-sales support and customer service

A hydraulic wrench’s durability and operational reliability depends heavily on strong after-sales support and customer service from the manufacturer. A trustworthy manufacturer must provide reputable post-purchase assistance which includes warranty protection alongside maintenance services and rapid responses to any customer questions. Look for a manufacturer that operates an efficient service network to quickly address any hydraulic wrench issues that might occur after purchase. Reducing operational downtime becomes possible through such preventive maintenance measures. A manufacturer which provides robust after-sales service shows dedication toward maintaining customer satisfaction and product quality.

5. Review the manufacturer’s innovation and technology integration

Technological advancement remains vital for hydraulic wrenches to adapt to changing industrial objectives in our current quick-moving world. Manufacturers who provide continuous innovation together with advanced technology integration deliver the best hydraulic wrench products. The inclusion of electronic torque control alongside lightweight construction and ergonomic features should be considered by modern manufacturers. Products that undergo research and development initiatives for improved performance reliability and user experience by manufacturers usually match contemporary standards. Choose manufacturers releasing equipment with modern technology because it delivers both operational precision and enhanced effectiveness.

6. Compare pricing and value for money

Before investing in a product, you should evaluate its price across multiple manufacturers to get excellent value. Hydraulic wrenches represent core operational equipment so buying the least expensive ones may lead to performance problems and increased long-term expenses. Manufacturers with both competitive pricing strategies and high-quality standards that deliver long-lasting products should be your choice when selecting a supplier. Your selection of a hydraulic torque wrench will achieve optimal value when you find a balance between cost and product quality.

The selection process for an optimal hydraulic torque wrench manufacturer demands several essential evaluations between product diversity and quality performance alongside existing market recognition, customer support attentiveness, technical innovation capabilities, and systematic financial arrangements. The elements you evaluate help you choose a hydraulic torque wrench manufacturer that provides durable, reliable, and efficient wrenches specifically designed for your requirements. Your operations will benefit from manufacturers who deliver high-quality tools at affordable rates, thus improving your operational performance and tool durability.