Introduction to Advanced Inspection Technologies

In today’s fast-paced industrial landscape, ensuring top-notch product quality is more important than ever. Quality Control Services are crucial for maintaining high standards, particularly in regions with bustling manufacturing hubs like China. The rise of advanced inspection technologies, such as AI, robotics, and IoT, is transforming quality control. These cutting-edge tools allow for faster, more accurate inspections, improving overall efficiency and reliability. This blog delves into how these technologies are reshaping quality control, highlighting their practical applications, benefits, and the exciting future trends they promise. Join us as we explore how AI, robotics, and IoT are revolutionizing the way industries ensure the highest quality standards for their products.

AI in Quality Control

Artificial Intelligence is revolutionizing quality control by enhancing inspection speed and precision. AI systems can process large datasets quickly, identifying defects and irregularities that human inspectors might miss. For instance, in the automotive industry, AI-driven vision systems scan parts for defects, ensuring they meet strict safety and performance standards. In electronics, AI algorithms detect faults in circuit boards with high accuracy, reducing the chances of faulty products reaching consumers. These advancements not only boost inspection accuracy but also cut down on the time and costs linked with manual checks. AI is thus a game-changer, bringing unprecedented efficiency to quality control.

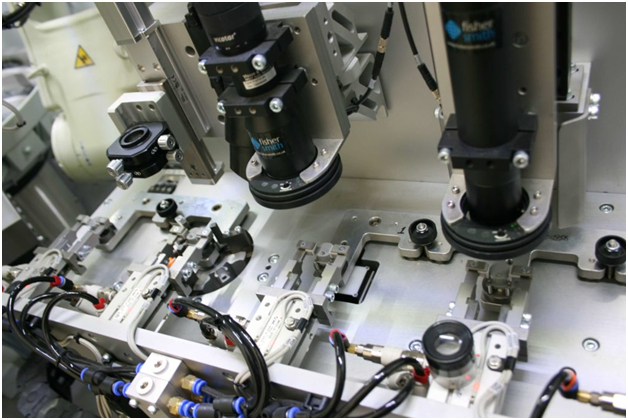

The Role of Robotics in Inspections

Robotics has revolutionized inspection processes, especially in risky or repetitive environments. Robots equipped with cameras and sensors can navigate areas too dangerous or hard for humans to access, like high-temperature zones or underwater locations. In manufacturing, robots carry out precise measurements and inspections nonstop, ensuring consistent quality. This automation frees human workers to focus on more complex tasks, improving overall efficiency. By enhancing safety and reliability, robotics makes quality control faster and more accurate, benefiting both manufacturers and consumers. The integration of robotics in quality control not only boosts productivity but also reduces the likelihood of errors, ensuring products meet high standards.

IoT and Its Impact on Quality Control

The Internet of Things (IoT) is transforming quality control in China by offering real-time monitoring and data collection. Smart sensors and connected machinery continuously track production conditions, allowing immediate action when issues arise. These devices also help with predictive maintenance by alerting operators to potential equipment failures, which minimizes downtime. By ensuring seamless communication between machines and systems, IoT significantly enhances the effectiveness of quality control services. For example, in the food industry, IoT sensors can monitor temperature and humidity in storage facilities, ensuring optimal conditions are maintained. This real-time oversight helps in maintaining high standards and catching potential problems before they escalate.

Integrating Technologies for Enhanced Quality Control

Integrating AI, robotics, and IoT in quality control creates a seamless and highly efficient system. AI’s data processing capabilities, combined with the precise, consistent work of robots, and IoT’s real-time monitoring, provide a holistic approach to maintaining high standards. For instance, AI can analyze data collected by IoT sensors, while robots perform detailed inspections based on this analysis. This synergy not only speeds up the inspection process but also enhances accuracy. However, implementing these technologies requires addressing challenges like system compatibility and data management. Standardized protocols and cloud-based platforms can help overcome these obstacles, allowing companies to fully leverage these advanced tools for superior quality control.

Case Studies: Successful Implementations

One example of successful implementation is a Chinese manufacturing company that integrated AI, robotics, and IoT into their quality control processes. This integration led to a 40% reduction in product defects and a 30% increase in production efficiency. The use of IoT devices also contributed to a noticeable decrease in downtime thanks to predictive maintenance capabilities. These technologies allowed the company to quickly identify and address potential issues, ensuring a smoother production flow. This case highlights the tangible benefits of adopting advanced inspection technologies, showcasing how they can enhance both product quality and operational efficiency in a real-world setting.

Future Trends in Quality Control Technologies

As we move forward, AI, robotics, and IoT will continue to revolutionize quality control. AI will advance to offer even more precise and autonomous decision-making, needing less human input. Robots will become smarter and more flexible, able to handle diverse inspection tasks with greater ease. IoT will evolve to provide even more detailed and real-time data, making it easier to monitor and adjust processes on the fly. We will see more integration between these technologies, creating seamless, automated systems that significantly enhance quality control in China. These improvements will make it easier for companies to maintain high standards, increase efficiency, and reduce costs, making advanced inspection technologies an essential part of future manufacturing.

Conclusion

In the rapidly evolving world of manufacturing, integrating advanced technologies like AI, robotics, and IoT into quality control processes is no longer a luxury—it’s a necessity. These technologies bring unmatched precision, efficiency, and reliability to inspections, ensuring that products meet the highest standards. AI’s ability to quickly analyze large data sets, the precision and consistency of robotics, and the real-time monitoring capabilities of IoT work together to create a robust quality control system. By staying ahead of these technological advancements, companies can ensure their products consistently meet the highest quality standards, fostering long-term success and customer loyalty.