When it comes to custom T-shirt printing, two of the most popular methods are Direct-to-Garment (DTG) printing and screen printing. Both techniques offer unique advantages and are suited for different business needs. Whether you are a small business owner, a designer, or a printing enthusiast, understanding the differences between DTG and screen printing can help you choose the best method for your needs. In this article, we will compare DTG vs screen printing on shirts in terms of print quality, cost, durability, and suitability for various applications.

What is DTG Printing?

Direct-to-Garment (DTG) printing is a modern printing method that works like an inkjet printer, applying water-based ink directly onto the fabric. This process allows for highly detailed and colorful designs without the need for extensive setup.

Pros of DTG Printing

- High-Quality Prints: DTG printing produces high-resolution designs with intricate details and smooth gradients.

- Unlimited Color Choices: Unlike screen printing, which requires separate screens for each color, DTG allows for full-color prints without extra cost.

- Great for Small Orders: Since there is no setup involved, DTG is cost-effective for small batches or single prints.

- Eco-Friendly: DTG uses water-based inks that are environmentally friendly and safe.

Cons of DTG Printing

- Higher Cost per Shirt: DTG ink is more expensive, making it less economical for large orders.

- Limited to Certain Fabrics: Works best on 100% cotton garments, and results may not be as vibrant on polyester blends.

- Slower Production Time: Printing each shirt individually can take more time compared to screen printing.

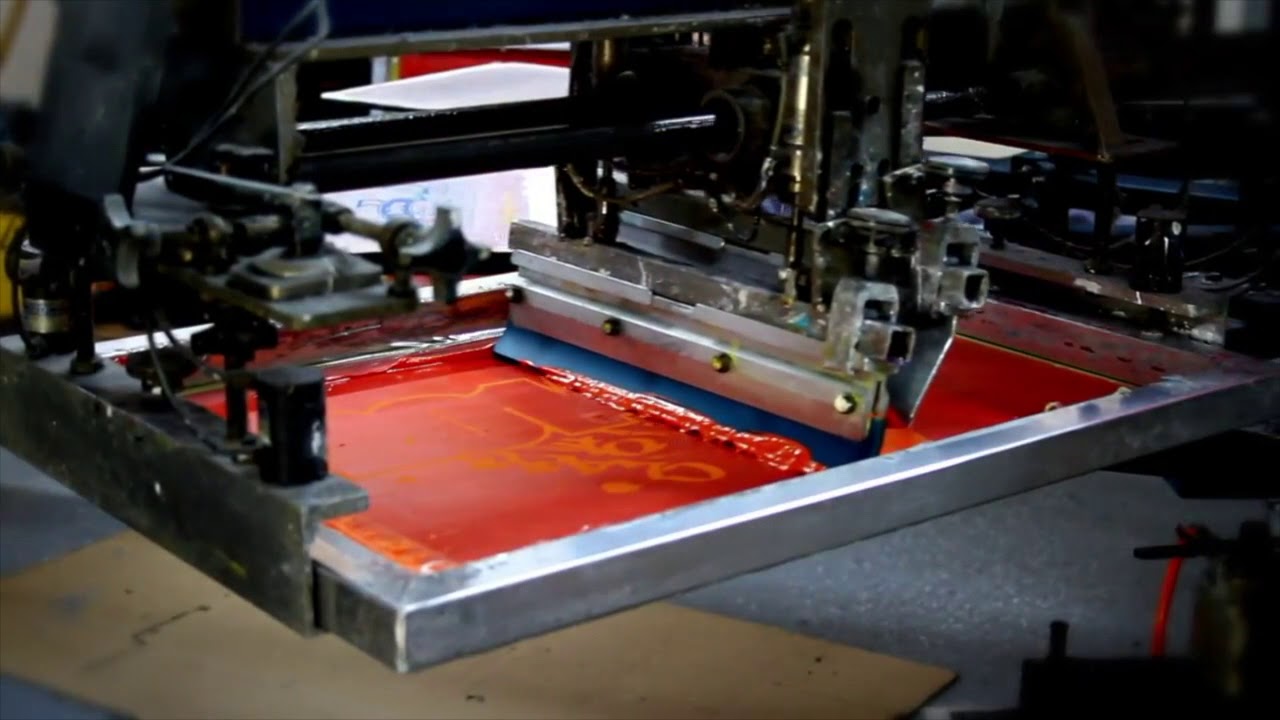

What is Screen Printing?

Screen printing is a traditional printing technique where ink is pushed through a stencil (or screen) onto the fabric. It is widely used for bulk orders and designs with fewer colors.

Pros of Screen Printing

- Cost-Effective for Large Orders: Once the screens are created, printing in bulk is fast and economical.

- Durable and Long-Lasting Prints: Screen-printed designs have a thick ink layer, making them more resistant to fading and cracking.

- Works on Various Fabrics: Can be used on cotton, polyester, blends, and even specialty fabrics.

- Vibrant Colors: Screen printing uses plastisol inks that create bold, opaque colors, especially on dark fabrics.

Cons of Screen Printing

- High Setup Costs: Each color in a design requires a separate screen, making multi-color prints expensive.

- Limited Color Choices: The number of colors in a design is restricted due to the complexity of creating multiple screens.

- Not Ideal for Small Orders: Because of the setup required, screen printing is not cost-effective for small batch printing.

DTG vs. Screen Printing: Key Comparisons

1. Print Quality

- DTG: Produces highly detailed prints with smooth gradients and complex designs.

- Screen Printing: Offers bold, vibrant colors but is less effective for intricate details.

2. Cost

- DTG: More expensive per shirt, but ideal for short runs.

- Screen Printing: High setup cost but cheaper for bulk orders.

3. Durability

- DTG: Prints may fade slightly over time, especially with frequent washing.

- Screen Printing: More durable and resistant to fading or cracking.

4. Best Use Cases

- DTG: Best for small orders, detailed artwork, and designs with many colors.

- Screen Printing: Best for bulk orders, simple designs, and long-lasting prints.

Which One Should You Choose?

The choice between DTG and screen printing depends on your specific needs:

- For small businesses or individuals printing custom shirts in small quantities, DTG is the better choice due to its flexibility and high-quality output.

- For businesses printing large quantities of shirts with simple designs, screen printing is the most cost-effective option thanks to its durability and efficiency in bulk production.

Conclusion

Both DTG and screen printing have their advantages and disadvantages. DTG is perfect for highly detailed, multi-color designs in small quantities, while screen printing is the best choice for large-scale production with vibrant, long-lasting prints. By understanding their differences, you can select the right method that suits your budget, order size, and design complexity.