When it comes to the automotive industry, tire machines play a crucial role in ensuring the smooth operation of vehicle maintenance. Whether it’s for mounting, demounting, or balancing tires, these machines are vital in every tire shop, garage, and auto repair facility. Understanding the various Tire Machine Parts and their functions is essential for technicians and owners who want to maximize their equipment’s lifespan and efficiency. This article will dive deep into the core components of tire machines, their functions, and why they are indispensable to any tire service.

Understanding Tire Machine Parts

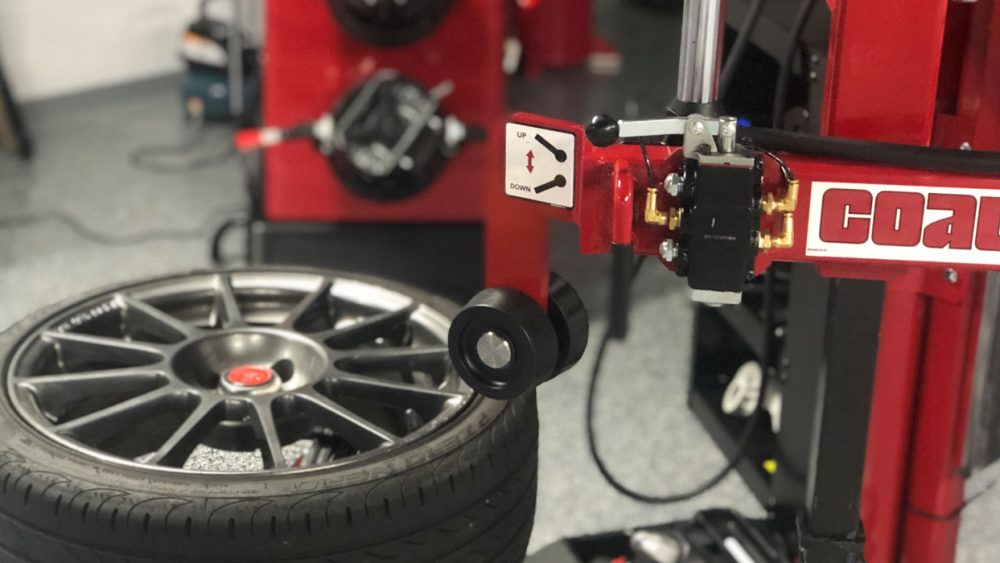

A tire machine is a sophisticated piece of machinery designed to make the process of installing and removing tires much easier, safer, and more efficient. These machines consist of several key parts that work together to handle the demanding tasks involved in tire maintenance. These parts include:

- Mounting Head

- Bead Breaker

- Turntable

- Rim Clamps

- Pneumatic System

- Lift Arms

- Control Panel

Each part serves a specific purpose, ensuring that tire installation, balancing, and maintenance are performed with precision.

Mounting Head: The Core of Tire Mounting

The mounting head is perhaps the most crucial part of any tire machine. It is the component responsible for guiding and pushing the tire onto the rim. The mounting head operates using a combination of hydraulic or pneumatic systems, which ensures that the tire is mounted evenly without damaging the tire or rim.

This part is equipped with a demounting tool that pushes the tire bead away from the rim during the removal process, allowing for a smooth tire change. Its robustness and durability make it essential for maintaining the performance of the tire machine.

Bead Breaker: Efficient Tire Disassembly

The bead breaker is a device used to break the tire bead’s seal with the rim, making it easier to remove the tire. Bead breakers are essential in tire machines, especially for tires that are tightly sealed to the rim. It usually operates with a hydraulic piston that provides sufficient force to detach the bead without causing damage to the tire or rim.

The bead breaker is typically adjustable to suit different rim sizes, ensuring versatility in handling various types of tires.

Turntable: The Rotating Mechanism for Tire Movement

The turntable is the component that holds the tire and allows it to rotate during the mounting and demounting process. It is the heart of the tire machine’s rotation system, facilitating precise movement while the technician operates the machine. Turntables come in different sizes, and they are adjustable to accommodate varying rim diameters.

The turntable is essential for maintaining the correct alignment of the tire and rim during installation, ensuring that the tire mounts evenly and securely. Additionally, the turntable’s smooth rotation helps to prevent any damage to the tire sidewalls and the rim itself.

Rim Clamps: Ensuring Proper Tire Holding

Rim clamps are crucial for holding the rim firmly in place while the tire is being mounted or dismounted. These clamps grip the rim’s edges securely, preventing any slippage or misalignment during operation. Rim clamps are usually operated by hydraulic or pneumatic systems and can adjust to fit various rim sizes.

The rim clamps not only ensure the stability of the tire but also protect the rim from damage. As rims are typically made from alloy or steel, it is important that the clamps provide a firm grip without causing scratches or dents on the rim’s surface.

Pneumatic System: The Driving Force

The pneumatic system is responsible for providing the necessary force for various functions within the tire machine. It uses compressed air to power components such as the mounting head, bead breaker, and rim clamps. Pneumatic systems are often preferred because of their reliability and the ease with which they can be maintained.

The system ensures that the tire machine operates efficiently, reducing the manual labor required and increasing overall productivity. With the right pressure, a pneumatic system can provide precise control over the various machine parts, ensuring that each task is performed correctly.

Lift Arms: Elevating the Tire for Easy Handling

The lift arms are essential for raising and lowering tires during the mounting and demounting process. These arms can be adjusted to different heights and are responsible for lifting the tire onto the turntable or removing it from the machine. They are designed to handle large, heavy tires with ease and ensure that the technician can work without straining themselves.

Lift arms typically use hydraulic systems to ensure smooth and safe tire movement. The ability to adjust the height of the arms makes tire handling more efficient, particularly for tires with different diameters and widths.

Control Panel: The Operator’s Command Center

The control panel is where the operator manages and controls the tire machine’s functions. It houses various buttons, dials, and switches that allow the technician to operate the machine’s parts with ease. Modern tire machines feature digital control panels that offer greater precision and ease of use.

The control panel is crucial for setting the tire machine’s parameters, such as adjusting the mounting head, turntable speed, or pneumatic pressure. It ensures that the machine is operating optimally, allowing the technician to complete the task quickly and efficiently.

Regular Maintenance and Care of Tire Machine Parts

To ensure the longevity of tire machine parts and maintain their efficiency, regular maintenance is required. Here are some key tips for keeping your tire machine in top condition:

- Lubricate moving parts: Regularly apply lubrication to the machine’s moving parts, such as the mounting head and bead breaker, to reduce wear and tear.

- Check pneumatic pressure: Ensure the pneumatic system is functioning correctly by regularly checking air pressure and inspecting for leaks.

- Inspect and replace worn components: Regularly inspect parts such as the rim clamps and lift arms for any signs of damage or wear and replace them as necessary.

- Clean the machine regularly: Dust and debris can accumulate in the tire machine, leading to decreased performance. Clean the machine regularly to prevent buildup and ensure smooth operation.

Conclusion

In conclusion, understanding the various tire machine parts is crucial for maximizing the efficiency, longevity, and performance of your tire servicing equipment. Whether it’s the mounting head, bead breaker, turntable, or rim clamps, each part plays an essential role in ensuring that tire installation and removal are carried out with precision and safety. Regular maintenance is also critical to keep your tire machine in optimal working condition.

By investing in quality tire machines and properly maintaining their parts, tire shops and auto repair facilities can improve their service offerings, reduce downtime, and enhance customer satisfaction.