The packaging industry has evolved dramatically in recent years, and one of the standout innovations is the heat shrink machine. This powerful technology has revolutionized the way products are packaged, ensuring that goods are protected, displayed effectively, and easier to transport. Whether it’s for food products, consumer goods, or industrial items, understanding how heat shrink machines work and the technology behind them is essential for any business aiming to improve its packaging efficiency and effectiveness.

What is a Heat Shrink Machine?

A heat shrink machine is a device that uses heat to shrink a plastic film around a product, creating a tight, secure package. The machine typically operates by applying heat through either a shrink tunnel or a heat-sealing process. The most commonly used plastic films for this process are polyethylene (PE), polyolefin (POF), and PVC, with the material choice depending on the nature of the product being packaged.

The process starts with a product being placed inside a plastic film, which is then passed through the machine. When heated, the film shrinks around the product, conforming to its shape, offering protection, tamper resistance, and an attractive presentation. The result is a sealed, durable package that protects the product from dust, moisture, and damage.

How Does a Heat Shrink Machine Work?

The operation of a heat shrink machine is fairly straightforward, but it involves several key components working in harmony to achieve optimal results.

1. Shrink Film Application

The first step involves wrapping the product in a shrink film. The film is typically fed into the machine by a conveyor system. Depending on the machine type, the film is either pre-made into a tube or applied directly over the product. This step must be done carefully to ensure the film is properly centered, as uneven wrapping can result in defects during the shrinking process.

2. Sealing the Package

Once the product is wrapped, the heat shrink machine uses heat to create a seal. The most common method of sealing is a heat-sealing bar or blade, which applies heat to the edges of the shrink film, causing them to fuse together. This creates an airtight and secure seal around the product, ensuring the film stays in place during the shrinking process.

3. Heating for Shrinkage

After the package is sealed, it is passed through a heat source that activates the shrinkage process. This is where a shrink film heat tunnel comes into play. The tunnel uses hot air, typically ranging between 300 to 600°F, to heat the film and cause it to contract around the product. The heat is distributed evenly to ensure the film shrinks uniformly, providing a snug fit.

A shrink film heat tunnel is designed to ensure that the temperature is carefully controlled to avoid overheating or damaging the product inside the packaging. The tunnel often includes a conveyor system that moves the wrapped products through the heated area, ensuring consistent results across large batches.

4. Cooling and Setting

Once the shrink film has fully contracted around the product, the machine cools the package to ensure the film hardens and sets. This cooling process is essential for maintaining the integrity of the package and ensuring it remains tight and secure during storage and transportation.

Key Benefits of Using a Heat Shrink Machine

1. Superior Protection

Heat shrink machines are excellent at providing protection to a wide range of products. The shrink film used creates a durable layer that shields the product from environmental factors such as dust, moisture, and contaminants. This is especially important in industries like food and beverage, pharmaceuticals, and electronics, where product quality and safety are of utmost importance.

2. Improved Shelf Appeal

In addition to protection, shrink-wrapped products have a smooth, professional appearance that enhances shelf appeal. This is especially beneficial in retail settings, where the packaging can influence consumer purchasing decisions. The tight, clear film allows customers to view the product while also providing a sleek, tamper-resistant barrier.

3. Cost-Effective

Heat shrink packaging is a cost-effective solution for many businesses. The materials used in shrink packaging are relatively inexpensive, and the automated nature of heat shrink machines means that companies can package large quantities quickly and efficiently. This reduces labor costs and increases productivity, making it a preferred choice for high-volume manufacturers.

4. Versatility

One of the key advantages of a heat shrink machine is its versatility. These machines can be used for a wide variety of products, from small consumer items to large industrial goods. Whether it’s a delicate cosmetic product or a heavy-duty industrial tool, the shrink-wrapping process can be adapted to fit the size and shape of virtually any item.

Types of Heat Shrink Machines

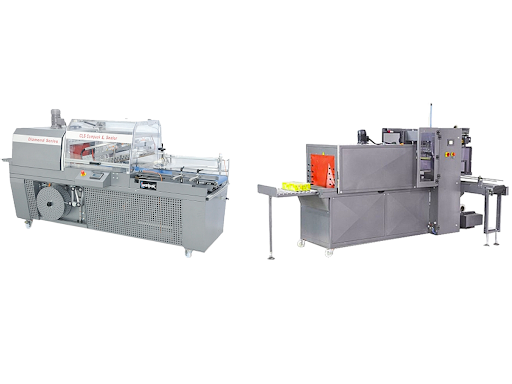

There are several different types of heat shrink machines available, each suited to different types of packaging applications. The two main categories include:

1. L-Bar Sealer Machines

These machines are ideal for sealing and shrinking individual products. They are typically used in situations where products are wrapped in film, sealed, and then shrunk in one continuous process. These machines are common in small to medium sized businesses that need quick, efficient packaging.

2. Shrink Tunnel Machines

For larger operations, shrink tunnel machines provide high-volume shrink wrapping. These machines are designed to handle continuous production lines and can accommodate multiple products at once. The shrink film heat tunnel is typically used with these machines to ensure even shrinkage across all products.

Conclusion

Understanding the technology behind heat shrink machines can help businesses make informed decisions when choosing the right packaging equipment. From providing enhanced protection to improving product presentation and reducing packaging costs, these machines offer numerous advantages. Whether you’re in the food industry, electronics, or retail, investing in a heat shrink machine can elevate your packaging process and ultimately drive business success.