As a writer and researcher, I frequently explore industrial innovations that enhance efficiency and safety. One such crucial component is Top heavy-duty casters, which are essential for equipment mobility across various industries. These specialized wheels play a vital role in facilitating seamless transportation, improving workplace safety, and extending the lifespan of machinery. In this article, I will delve into the importance of these casters, their benefits, and why they are a necessity for heavy-duty applications.

Understanding Heavy-Duty Casters

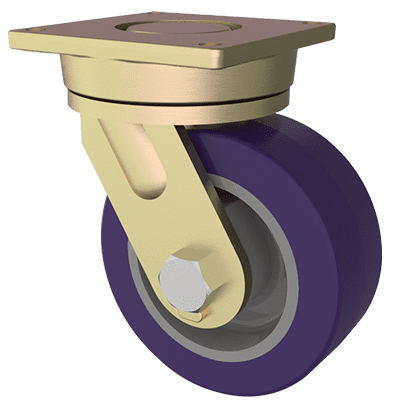

Heavy-duty casters are robust wheels designed to support significant weight while ensuring smooth mobility. Unlike standard casters, they are reinforced with high-quality materials such as forged steel, polyurethane, or cast iron to handle demanding industrial environments. These casters are widely used in warehouses, factories, medical facilities, and automotive industries, where equipment movement is frequent and crucial for operational success.

Why Heavy-Duty Casters Are Essential

The significance of using high-performance casters goes beyond just mobility. Below are some of the key reasons why industries and businesses should consider investing in them:

1. Increased Load Capacity

Heavy-duty casters are designed to support substantial weight without compromising performance. Whether transporting machinery, warehouse racks, or large containers, these casters provide reliable support, preventing damage to both equipment and flooring.

2. Enhanced Durability

Manufactured with premium materials, these casters offer superior resistance to wear and tear. Unlike standard wheels, which may degrade over time, high-quality casters ensure longevity, reducing the need for frequent replacements.

3. Improved Safety Standards

Using durable casters prevents workplace accidents caused by equipment instability. Many casters are equipped with braking mechanisms and locking systems that enhance safety by keeping heavy loads securely in place when needed.

4. Superior Maneuverability

Heavy-duty casters come in various designs, including swivel casters that provide 360-degree rotation. This feature is particularly useful in tight spaces where maneuverability is essential, such as manufacturing plants and hospitals.

5. Resistance to Environmental Factors

These casters are designed to withstand extreme temperatures, moisture, and exposure to chemicals. Industries such as food processing and pharmaceuticals benefit from corrosion-resistant casters that ensure consistent performance in harsh environments.

Types of Heavy-Duty Casters

Understanding the different types of casters helps in selecting the right option for specific applications.

1. Rigid Casters

These casters are fixed in one direction, making them ideal for straight-line movement. They offer excellent stability and are commonly used for heavy industrial machinery.

2. Swivel Casters

Swivel casters provide greater flexibility by allowing 360-degree rotation. They are perfect for carts, medical equipment, and warehouse trolleys that require frequent directional changes.

3. Locking Casters

Equipped with a braking system, locking casters prevent unintended movement. They are essential in applications where stationary positioning is required.

4. Pneumatic Casters

These casters have air-filled tires that provide a cushioned ride, making them suitable for rough terrain and outdoor use.

5. Spring-Loaded Casters

Designed to absorb shocks, these casters are ideal for transporting fragile equipment in industries such as electronics and medical research.

Applications of Heavy-Duty Casters

Due to their versatility, these casters are widely used in multiple sectors:

- Warehousing and Logistics: Heavy-duty casters enable easy transportation of inventory, reducing strain on workers and preventing workplace injuries.

- Automotive and Aerospace: Used in assembly lines and aircraft maintenance carts for secure and smooth mobility.

- Medical and Healthcare: Found in hospital beds, surgical carts, and diagnostic equipment to ensure efficient movement in healthcare settings.

- Retail and Hospitality: Utilized in shopping carts, luggage transport systems, and commercial kitchen setups for seamless operations.

- Manufacturing Industry: Essential for moving raw materials, conveyor systems, and production machinery.

Choosing the Right Heavy-Duty Casters for Your Needs

Selecting the appropriate casters depends on various factors, including:

- Weight Capacity: Consider the maximum load the casters need to support.

- Wheel Material: Opt for polyurethane, rubber, or steel based on the application’s environmental conditions.

- Mounting Type: Choose between plate-mounted or stem-mounted casters depending on the equipment.

- Surface Compatibility: Ensure the casters can function efficiently on the floor type (e.g., concrete, tile, or carpet).

Conclusion

Heavy-duty casters are a fundamental component in industrial and commercial settings, offering durability, safety, and efficiency. Their ability to support heavy loads, resist environmental challenges, and improve maneuverability makes them a worthwhile investment for any business. As a researcher, I find that technological advancements continue to enhance the functionality of these casters, making them indispensable for industries that prioritize safety and performance. Choosing high-quality casters ensures long-term reliability and smooth operations, reducing downtime and maintenance costs in the long run.